''The system refrigerant starts its cycle in a gaseous state. The compressor pumps the refrigerant gas up to a high pressure and temperature. From there it enters a heat exchanger (sometimes called a condensing coil or condenser) where it loses energy (heat) to the outside, cools, and condenses into its liquid phase''

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor.

Compressors are similar to PUMP: both increase the pressure on a fluid and both can transport the fluid through a pipe. As gases are compressible, the compressor also reduces the volume of a gas. Liquids are relatively in compressible; while some can be compressed, the main action of a pump is to pressurize and transport liquids.

There are basically 5 types of air conditioner compressor that are commonly used in the HVAC industry:

- Reciprocating.

- Scroll.

- Screw.

- Rotary.

- Centrifugal.

There are basically 5 types of air conditioner compressor that are commonly used in the HVAC industry:

Reciprocating Air Conditioner Compressor

The reciprocating compressor uses piston to compressor the refrigerant driven by a crankshaft in a straight line back and forth motion. This rotary motion is achieved by the use of an electric motor and the construction is quite similar to that of an automobile engine.

The piston moves up and down inside a cylinder. Vapor from the suction line is moved through the intake valve as the piston move downward. As the piston moves upward, it compresses the vapor refrigerant which is then pushed through the exhaust valve into the condenser.

The compressor may has more than one cylinder which is also known as multi-cylinder compressor. The common ones are the two-cylinder, four-cylinder and eight-cylinder compressors

Scroll

A scroll compressor has one fixed scroll which remains stationary and another moving or orbiting scroll that rotates through the use of swing link. When this happens, the pockets of refrigerant between the two scroll are slowly pushed to the center of the two scrolls causing the reduction of the volume of the gas. It is then discharged though the center port to the condenser.

The advantage of scroll compressor is that it has fewer moving parts and less torque variation compared to the reciprocating compressor. This advantage is translated to a smooth and quiet operation.

The advantage of scroll compressor is that it has fewer moving parts and less torque variation compared to the reciprocating compressor. This advantage is translated to a smooth and quiet operation.

The scroll compressor is also known as scroll pump or scroll vacuum pump.

Screw

Screw

The screw compressor uses a pair of helical rotors where it traps and compresses the gas as the rotors revolve in the cylinder. In HVAC,

they are usually used in systems with 20 ton capacity and above. The male rotor and the female rotor are built inside the cylinder. The low pressure refrigerant enters one end of the compressor and the resultant high pressure refrigerant is discharged into the opposite end to the condenser.

Rotary

The rotary compressor can be divided into two types. One has blades or vanes that rotate with the shaft. The other type has the blade which remains stationary and is part of the compressor housing assembly. In both types, the vapor from the suction line is drawn into the cylinder through the suction port.

As the blade rotates, trapped vapor in the space ahead of the blade is compressed into high pressure gas after which it is discharged to the condenser through the exhaust port. The number of blades can range from two to eight in a single system.

Centrifugal

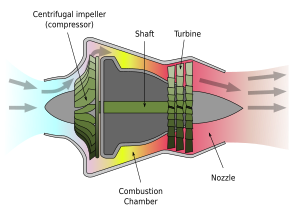

Centrifugal compressor is usually used in large capacity refrigerating system. In this compressor, the vapor is moved in a circular motion known as centrifugal force. An impeller which is a disk with radial blades spins rapidly inside this housing causing the gas to gain velocity.

A diffuser converts this energy into pressure energy and is then discharged into the condenser. The pumping efficiency increases with speed, hence this type of compressors are designed to operate at high speed.

The main advantage of centrifugal compressor is that there are no valves, pistons or cylinders. The wearing parts that need attention are the main bearings.

A centrifugal compressor is a type of dynamic compressor, or turbo compressor, with a radial design. Unlike displacement compressors that work at a constant flow, dynamic compressors work at a constant pressure and the performance is affected by external conditions such as changes in inlet temperatures

No comments:

Post a Comment